Boxmaker for the production of FEFCO flap packaging made of 3- and 5-layer corrugated cardboard: E, B, C, BE and BC.

Carton puncher

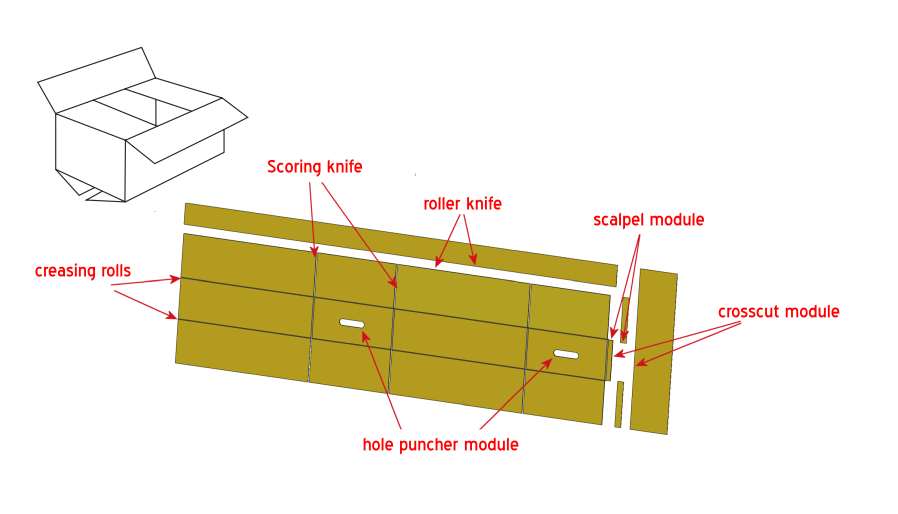

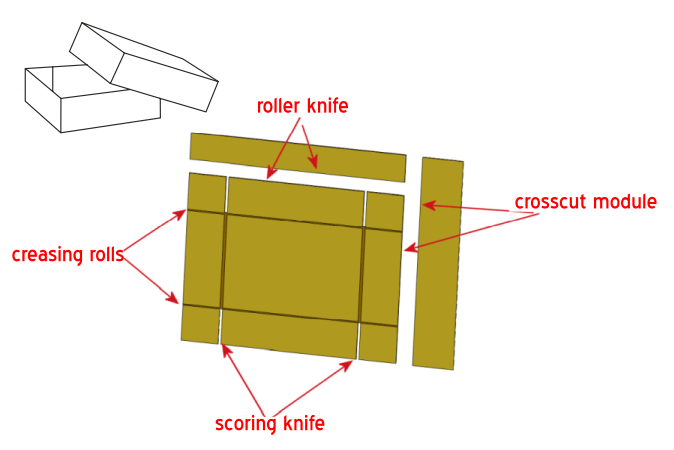

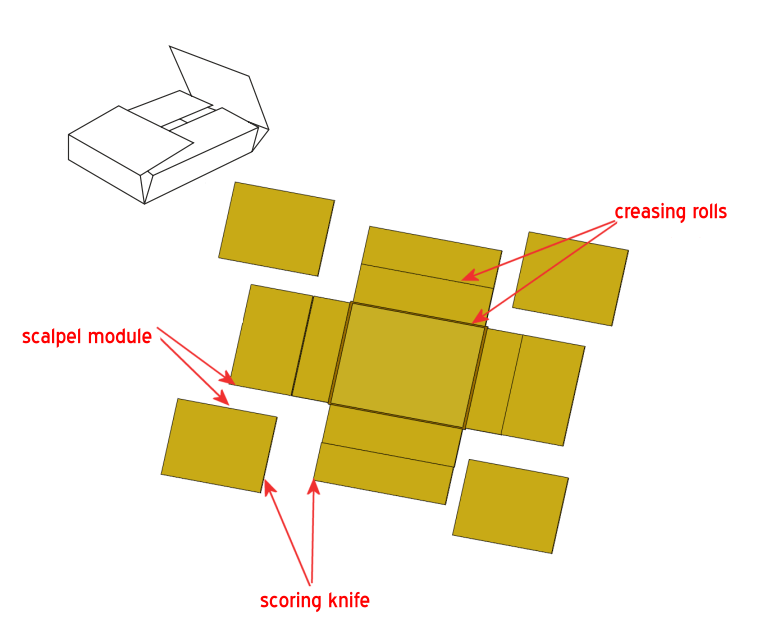

The machine in one cycle* performs the following operations:

- gets a sheet from the table

- creases the mat crosswise and lengthwise

- cuts the form to the appropriate format if it is larger

- cuts slots in a flap package

- makes holes for the so-called "handles" or under ventilation

- cuts off the mat's allowance along the width

- cuts off the excess adhesive flap

- does printing

- applies glue to the glue flap

- throws the finished box onto the pallet

* applies to a fully configured machine.

In this form, the packaging is ready for stapeling/gluing.

It takes about 3 - 6 minutes to convert the machine to produce a different size package, and in the automatic version this time is reduced to less than 1 minute. The operator enters the dimensions of the package into the computer via the touch panel and only sets the creasing rollers and moves the knife to them. In the automatic version of the machine, the operator only enters the dimensions without any additional intervention.

Boxmaker

can also be used for creasing cardboard as well as for cutting it with rotary knives.Machine parameters

| Bandwidth | ~85m/min of creasing |

| 3-layer cardboard | flute B, C, E |

| 5-layer cardboard | flute BC, BE |

| Working width | 2500mm |

| Maximum package height (for 300mm slotting knives) | |

| Maximum sheet length | unlimited | 1900mm |

| Maximum height of the form | approximately 2450mm |

| Touchpad | Yes |

| Creasing rollers | 2 sets (crease roll + counter crease) |

| Required operators | 1 person |

| Rotary cutting knives | 1 set |

| Power | 400V |

| Weight | approx. 2600 kg |

| Compact dimensions | 305x100cm |

A fully customizable machine for your needs

During the ordering process, the customer can choose not only the width of the machine (from 1250 to 3000 mm), but also decide to equip it with additional modules according to his preferences.

Additional options

- Cross cut module (motor or pneumatic)

- Scalpel knives(rotary or straight)

- Slotting knives (slots from 50 to 500mm)

- Mini Automatic flexographic printer

- Automatic feeder (roller or vacuum)

- Auto Receiver

- Automatic setting of creasing rollers

- Automatic setting of slotting knives

- Automatic scalpel knife setting

- Die-cut module

- Quick order setup and management: Boxmanager.pl

- Roller knives

- Remote control possible via Tablet/Smartphone